What configurations are most important when replacing connectors? — Taking a tactile switch as an example

In electronics manufacturing, connector and switch replacements are a common requirement. Engineers often consider alternatives due to manufacturer discontinuation, long lead times, cost pressures, or the need to optimize product performance.

So, which configurations are most important to focus on when replacing connectors?

Core configuration parameters

Electrical performance

Rated current/voltage

Contact resistance, insulation resistance

Whether it meets high-frequency/high-speed or automotive-grade applications

Mechanical properties

Insertion life (cycles)

Insertion force/extraction force

Vibration and shock resistance

Environmental adaptability

Operating temperature range

Water and dust resistance rating (such as IP67/IP68)

Salt spray resistance, corrosion resistance, flame retardant grade

Size and structure

Dimensions, mounting method (DIP / SMT)

Pin pitch and arrangement

Matching with PCB size/housing

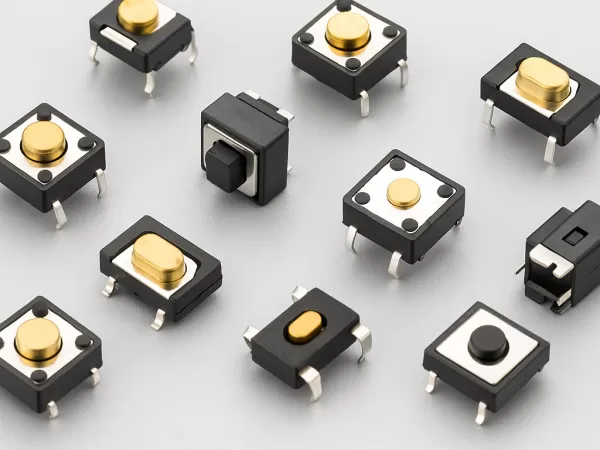

Case: Tactile Switch

When changing the type of touch switch, special attention should be paid to:

Actuation Force : Determines the feel and user experience

Travel : affects feedback sensitivity

Lifetime : Common ones include 50K, 100K, 500K, etc.

IP rating : Outdoor or home appliances often require IP67 waterproof and dustproof

Our Advantages

At EasyChips Connector, we can provide our customers with:

Standard connector series : USB, FPC, Wire-to-Board, etc.

Tactile & waterproof switch solutions

OEM / ODM customization to ensure compatibility with original replacements

CE / RoHS certified to meet European and global market requirements

Fast samples with competitive prices

If you are considering an alternative to a connector or switch, please contact us and we can quickly recommend an equivalent model or provide a customized solution .