Behind the Scenes at EasyChips Connector

Have you ever wondered how connectors and tactile switches are made before they arrive in your hands?

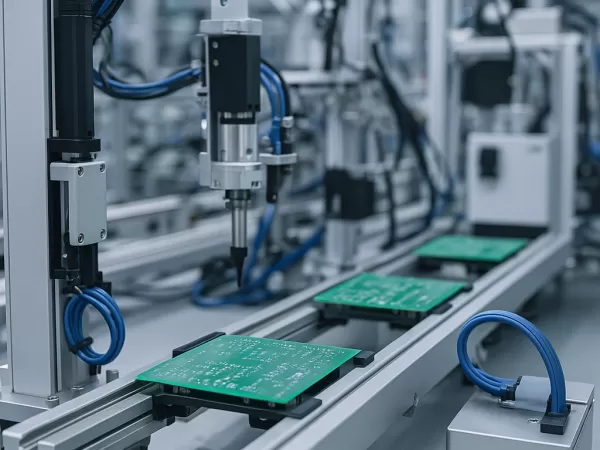

At EasyChips, we take pride in our automated production lines and strict quality control processes. From raw materials to finished connectors, every step is carefully managed to ensure precision, reliability, and compliance (CE / RoHS / IATF 16949).

Production Highlights

Stamping & molding workshops – for high-precision terminals and housings

Automated assembly lines – ensuring consistency and reducing defects

Quality testing labs – vibration, salt-spray, and high-temp reliability checks

Customized solutions – tailored connectors and switches based on client needs

We believe transparency builds trust — and we’re excited to share these behind-the-scenes moments with our global partners.

Please contact us if necessary.