Do you know the relationship and difference between PCB, FPC and FFC?

FPC (Flexible Printed Circuit), PCB (Printed Circuit Board), and FFC (Flexible Flat Cable) are three different types of circuit carriers and connectors, each with its own specific uses and characteristics. The following are their relationships and differences:

1. PCB (Printed Circuit Board)

definition:

PCB refers to printed circuit board, which is a non-bendable rigid board used to connect electronic components in electronic devices.

Features

- Rigidity : PCBs are usually made of fiberglass and epoxy resin and are not bendable.

- Multi-layer structure : There can be multiple conductive layers, suitable for complex circuit design.

- High density : supports high-density wiring, suitable for applications with complex circuits and dense components.

- Mechanical stability : High mechanical strength, suitable for electronic devices that need to be stably fixed.

application

It is widely used in various electronic products such as computers, communication equipment, home appliances, automotive electronics, etc.

2. FPC (Flexible Printed Circuit)

definition:

FPC refers to flexible printed circuit board, which is a circuit board that can be bent and folded, usually made of polyimide or polyester film.

Features

- Flexible : Can be bent and folded, suitable for applications with limited space and complex shapes.

- Lightweight : Lightweight and suitable for portable electronic devices.

- Durability : High temperature and chemical resistance.

- Single or multi-layer : It can be single-layer, multi-layer or double-sided structure.

application

Mainly used in mobile devices (such as mobile phones, tablets), wearable devices, printers, cameras, monitors, etc.

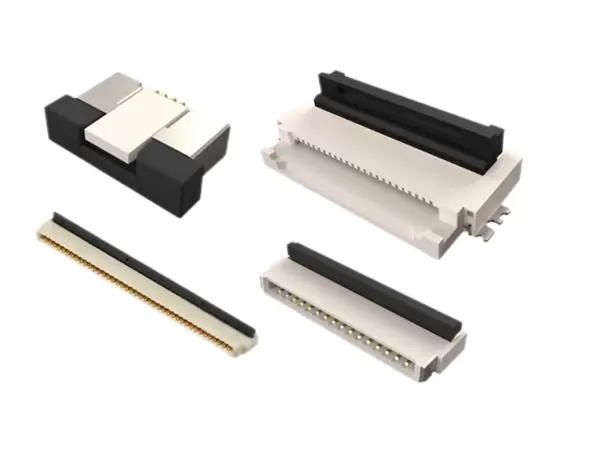

3. FFC (Flexible Flat Cable)

definition:

FFC refers to flexible flat cable, which is a parallel array of conductors, sometimes also called flat cable or flat cable.

Features

- Flexible : Can be bent, but not as complex as FPC.

- Flat design : Saves space and fits in compact devices.

- Standardization : Usually has a standard pitch and number of pins to facilitate production and installation.

- Multiple connection methods : can be connected by welding, connectors, etc.

application

Widely used in printers, scanners, monitors, laptops, camera modules, home appliances and other applications that require multi-core flat cables.

Relationship and difference

FPC vs. PCB :

- Flexibility : FPC is flexible and can be bent and folded, while PCB is rigid and cannot be bent.

- Application scenarios : FPC is used where flexible connections are required, such as connections inside mobile devices, while PCB is used in applications with fixed structures and high mechanical stability, such as computer motherboards.

- Manufacturing materials : FPC usually uses polyimide or polyester film, while PCB uses fiberglass and epoxy resin.

FFC vs. FPC :

- Complexity : FFC is a relatively simple flat cable, mainly used for simple multi-core cable connections; while FPC can be a complex circuit board containing components and multiple layers of wiring.

- Structure : FFC is usually a conductor strip arranged in parallel with a simple structure; FPC can be a single-layer or multi-layer circuit with a complex structure.

- Connection method : FFC is mostly used for plug-in connectors, and FPC can be connected by welding, connectors, etc.

Summarize

- PCBs are rigid boards used in applications that require mechanical strength and stability.

- FPC is a flexible board used in applications that require flexibility and foldability.

- FFC is a flexible flat cable used for simple connection applications that require a multi-core flat cable.

Understanding the characteristics and application scenarios of these circuit carriers and connectors will help you choose appropriate solutions in the design and manufacture of electronic products.

Easychips Precision Technology Co., Ltd. is a global leading connector manufacturer, focusing on designing, producing and selling high-quality connectors and interconnect solutions.

If interested, please contact: Lilian@easychipsconnector.com