"Environmental protection and high efficiency: How FPC promotes green electronic manufacturing"

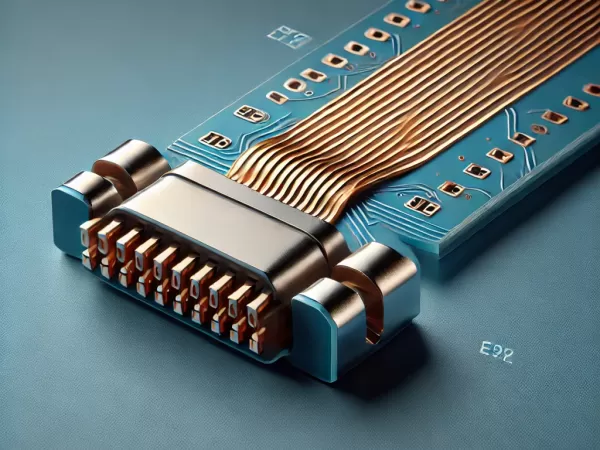

As global environmental awareness increases, all walks of life are exploring how to promote technological innovation in a greener and more efficient way. In the field of electronic manufacturing, **FPC (flexible printed circuit board)**, as an emerging technology, is leading a green revolution.

1. Reduce material waste and optimize production efficiency

FPC, with its light and flexible characteristics, greatly reduces the material consumption of traditional PCB (printed circuit board) in production. Compared with rigid circuit boards, the bendability of FPC means that it can adapt to more complex and compact product designs, which helps to reduce the use of materials, optimize the production process, and thus reduce resource waste.

2. Reduce energy consumption and carbon footprint

During the manufacturing process, the production process of FPC requires less energy than traditional PCB. This means that the production of each FPC is reducing the overall carbon footprint of the manufacturing industry. As the global demand for electronic products continues to grow, FPC has become an important choice for manufacturers to reduce environmental impact through its environmental friendliness.

3. Support lightweight and miniaturization of electronic products

FPC is not only environmentally friendly, but also helps miniaturize and lighten electronic products. This feature is particularly significant in the fields of mobile phones and wearable devices. With reduced product weight and improved energy efficiency, FPC has become an ideal partner for the sustainable development of smart devices. It can also increase the design freedom of electronic devices, reduce the complex internal connection lines of the device, and effectively improve product performance and production efficiency.

4. Extend device life and reduce electronic waste

The high durability and flexibility of FPC make it excellent in withstanding bending and mechanical stress, which means it can extend the service life of electronic products. As the life cycle of the equipment is extended, the generation of electronic waste will be significantly reduced, making an important contribution to environmental protection.

5. Promote the future of green manufacturing

In the context of global sustainable development, green manufacturing is no longer a choice, but a trend. As one of the representative technologies of environmentally friendly electronic manufacturing, FPC is driving the manufacturing industry towards a more efficient and low-carbon direction. For enterprises, the use of FPC not only helps to upgrade product technology, but also meets the growing demand for environmental protection and enhances brand image.

By adopting FPC, your company can not only improve production efficiency, but also make positive contributions to the future of the earth. Let us work together to move towards a new era of green electronics manufacturing! Welcome to discuss more with us!