"FPC Connectors: The Ideal Solution for High-Density, Lightweight PCB Connections"

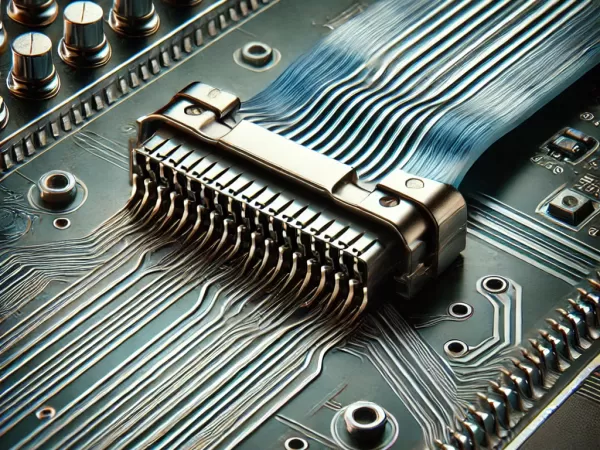

As electronic devices become increasingly miniaturized and highly integrated, how to achieve efficient circuit connections has become a key challenge facing designers. In this context, FPC (flexible printed circuit) connectors stand out as an ideal choice for high-density, lightweight PCB connections. Whether in smartphones, tablets, or wearable devices, FPC connectors have brought new possibilities to product design with their unique advantages.

1. Ultra-thin design, saving space

One of the biggest advantages of FPC connectors is their ultra-thin design. Compared with traditional rigid connectors, FPC connectors can not only significantly reduce the space occupied by the connector, but also easily adapt to curved and complex structures. This makes it very suitable for space-sensitive design requirements in small devices, such as smartphones, tablets, and VR devices.

2. High-density connection to achieve multi-functional integration

With its precise pin design, the FPC connector can support high-density circuit connections. This means that more signals and data can be transmitted through the same connector, ensuring the improvement of device functional integration. This feature of the FPC connector is particularly important in electronic devices that require multi-signal transmission.

3. Lightweight, improve product portability

Modern electronic devices are pursuing powerful functions while also requiring increasingly lighter weight. FPC connectors are made of flexible materials and are lightweight, which can effectively reduce the overall weight of the device and help achieve a perfect balance between portability and high performance. For applications such as wearable devices and drones, the lightweight design of FPC connectors is particularly critical.

4. High durability to meet harsh environmental requirements

Although FPC connectors are known for their lightness, they are also very durable. Made of high temperature and wear-resistant materials, FPC connectors can work stably under complex industrial and environmental conditions, ensuring that the equipment maintains reliable performance during long-term operation.

5. Widely used, flexible to meet different needs

Whether in consumer electronics, automotive electronics, industrial automation and other fields, the application of FPC connectors is constantly expanding. Its high flexibility and adaptability enable it to cope with a variety of complex connection requirements and is an indispensable component in the design of future electronic devices.

As electronic products become more diverse and high-performance, FPC connectors have become an ideal solution to meet the needs of modern electronic design due to their high density, light weight, durability and flexibility.

Choosing FPC connectors means opening up unlimited possibilities for your devices. Welcome to discuss with us.