"From Principle to Application: Analysis of the Working Mechanism of DIP Switches"

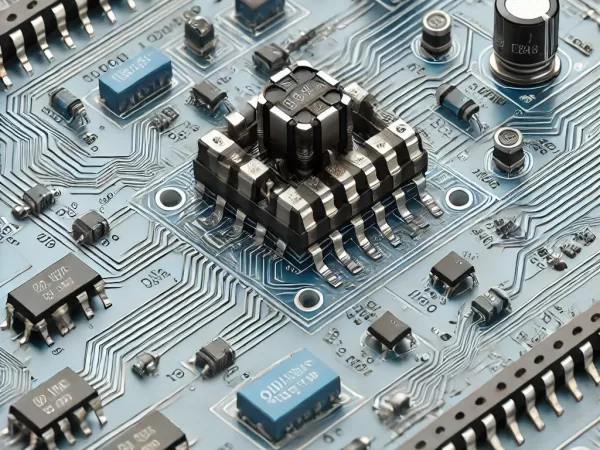

As a simple and efficient physical switch device, the DIP switch plays an important role in modern electronic devices and embedded systems. Its original design was to achieve the function selection of circuits or devices through a simple "on/off" state. Although it looks simple in structure, the working mechanism of the DIP switch can effectively solve the problem of complex circuit configuration and device mode switching. This article will start from the technical principle of the DIP switch and analyze its actual role in different applications in detail.

The basic principle of DIP switch

A dip switch is a physical binary switch, each switch corresponds to two states: ON or OFF . Its operation is similar to the switches we use in daily life, but the difference is that the dip switch is usually installed on a circuit board to control different parts of the circuit or select a specific function or mode.

Each DIP switch position represents a binary "0" or "1" state. By combining the positions of multiple switches, engineers can define a variety of different functions or configurations. For example, a 4-bit DIP switch can achieve 24=162^4 = 1624=16 different combinations, helping engineers and users easily switch between multiple functional modes.

Internal structure of the DIP switch

Although the design of the DIP switch is simple, its internal structure is sophisticated. It usually includes the following main parts:

- Switch lever or toggle : This is the part that the user uses to change the state of the switch. When the user flips the switch, its mechanical design connects or disconnects the contacts inside the switch to the circuit.

- Contacts : Contacts are the key to achieving electrical connections. When the switch is turned to "on", the internal contacts close, thereby conducting current; when the switch is turned to "off", the contacts open and the circuit is disconnected.

- Shell : The shell is usually made of insulating material and plays a role in protecting the switch to prevent the contacts from being exposed and causing short circuits or poor contact.

Working mechanism of DIP switch

The core principle of the DIP switch is to control the circuit state by closing or opening the mechanical contacts . The working process of the DIP switch is as follows:

- Physical toggle : When the user flips the switch lever, the internal contacts move, connecting or disconnecting the circuit to the output of the switch.

- Signal input/output : When the contacts are closed, current can pass through the switch, thereby changing the state of the entire circuit; when the contacts are open, the circuit is in an open state.

- Combination control : By combining the positions of multiple dip switches, complex control logic can be implemented, such as selecting different voltage or current paths or activating specific functions.

This mechanical design ensures that the DIP switch has high reliability and stability, and is especially suitable for situations where a fixed configuration needs to be maintained for a long time.

Common applications of DIP switches

Embedded system configuration In embedded system design, dip switches are often used to select the system's operating mode, address encoding, or hardware configuration. For example, developers can flip a dip switch to change the pin function of a microcontroller or select the operating mode that the device uses at startup.

Communication settings for industrial equipment Industrial automation equipment often requires dip switches to set the device address, communication protocol or baud rate. By manually adjusting the switch position, engineers can quickly configure the parameters of the device without reprogramming or operating through complex user interfaces.

Mode switching in consumer electronics Many home electronic devices, such as air conditioners, stereos, or televisions, use dip switches to switch between functional modes. Users can change the device's operating mode or preset function by adjusting the dip switch without having to perform cumbersome key operations.

In network devices (such as routers or switches), dip switches are often used to select the network mode of the device or set the IP address of the device. Users can easily adjust the network configuration through physical switches, which facilitates the rapid deployment and management of devices.

Advantages of DIP switches

Simple and intuitive : The operation of the dip switch is very simple. You can change the configuration of the device by simply turning the switch manually. This is especially convenient for users who are not familiar with programming or complex configuration.

High reliability : Since the DIP switch adopts mechanical contact design, it has high reliability and can maintain stable performance even in harsh environments (such as high temperature, high humidity or vibration environment).

Cost saving : Compared with software or digital switches to achieve function control, the cost of dip switches is low. It is suitable for occasions that require simple, fixed configurations, such as industrial equipment or embedded systems.

Long life : DIP switches are designed to withstand thousands or even tens of thousands of switching operations, making them suitable for long-term use without failure or performance degradation.

With its simple, intuitive and reliable design, DIP switches have become an important control element in electronic devices. From embedded systems to industrial equipment, DIP switches have demonstrated their unique advantages in various application scenarios. By understanding its working principles and application scenarios, engineers and developers can better use DIP switches to achieve efficient control in complex systems.

In the future, as electronic equipment develops, DIP switches will continue to play an important role in flexible configuration, simplified operation and improved system reliability.