The differences between touch switches and membrane switches are as follows...

Date:2024-09-10

Although both touch switches and membrane switches are used for the operation and control of electronic devices, they are obviously different in structure, working principle, usage scenarios, etc. The following are their main differences:

1. Structure and design

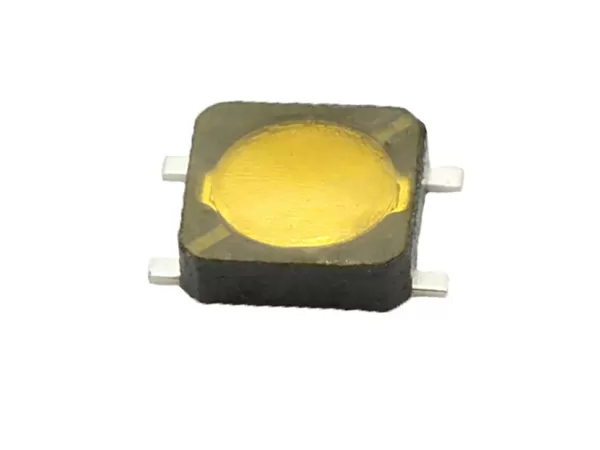

- Touch switch : Touch switch is a mechanical switch, usually composed of a shell, a spring, a button, etc. When pressed, the metal spring inside contacts the contact point to form a circuit; when released, the spring returns to its original position and disconnects the circuit. It has a distinct "pressing feeling".

- Membrane switch : A membrane switch is a flat switch made of multiple layers of thin film materials. It usually has two layers of circuits, upper and lower. When pressed, the upper and lower circuits touch each other to complete the circuit conduction. Its structure is flatter and more flexible than a touch switch, and the surface is usually covered with materials such as PET and PC.

2. Working Principle

- Tactile switch : Based on the elastic rebound principle of mechanical buttons, the circuit is closed or disconnected by pressing. A certain amount of force is required to operate, and there is clear pressing feedback.

- Membrane switch : The two conductive layers in the circuit are contacted by pressing to complete the circuit conduction. Usually there is no obvious mechanical feedback, and the operation is completed by pressing the contact point.

3. Operation experience

- Touch switch : It has a more obvious pressing feel and sound feedback. When pressed, you can feel a "click" sound, and the user can clearly feel whether the operation is effective.

- Membrane switch : There is generally no mechanical feedback when pressed, or the feedback is very weak. The operation is smoother and quieter, and it is suitable for environments that require quiet operation.

4. Appearance and thickness

- Touch switch : It has a small appearance but a certain thickness, suitable for installation on PCB circuit boards, and is often used in more three-dimensional equipment.

- Membrane switch : very flat, very thin, often attached to the surface of equipment, such as the panel of electronic instruments, home appliances, medical equipment, etc.

5. Service life

- Tactile switch : A mechanical switch with a limited number of key presses, generally around 100,000 to 1 million times . The specific lifespan varies depending on product quality and design.

- Membrane switch : Since it is a conductive diaphragm contact without mechanical wear, its life is usually longer, generally up to 1 million to 5 million times or more, and it is suitable for high-frequency operation scenarios.

6. Application scenarios

- Touch switch : widely used in situations where clear operational feedback is required, such as home appliances, consumer electronics, communication equipment, remote controls , etc. Suitable for devices where users require a strong sense of pressure and mechanical feedback.

- Membrane switch : commonly used in flat control panels, such as medical equipment, industrial control, household appliances, electronic toys, instruments , etc., especially in situations where dustproof and waterproof design is required.

7. Customization and Appearance

- Tactile switch : The appearance and design are relatively fixed, and the customization options of color, shape and size are limited.

- Membrane switch : Due to the use of printing technology, the surface can be personalized, with printed patterns, logos, text, etc. It has high customization flexibility and is suitable for control interfaces that require aesthetics.

8. Price

- Tactile switch : Relatively low production cost, widely used in consumer electronics.

- Membrane switches : Due to the need for customized printing and multi-layer structures, the cost is relatively high, especially for membrane switches with complex designs or waterproof and dustproof functions.

Summarize

- The touch switch is suitable for scenarios that require clear pressing feedback and mechanical feel. It has a relatively simple structure but is relatively thick.

- Membrane switches are flatter and more flexible, suitable for applications that require a beautiful appearance, protective features, and a long lifespan. They are quieter to operate and have a high degree of design customization.

Both are widely used in their respective fields according to different application requirements.